As part of UKAS’s commitment to provide a consistent and robust accreditation service to the asbestos sector UKAS reviews its asbestos-related policies, procedures and requirements on an ongoing basis through the Asbestos Technical Advisory Committee (a list of committee members is available on the UKAS website www.ukas.com. UKAS also continues to discuss the assessment of the requirements of ISO/IEC 17020, ISO/IEC 17025 and sector-related publications, to ensure a consistent assessment approach, during its regular Asbestos Technical Assessor meetings.

UKAS will publish Technical Bulletins relating to accreditation within the asbestos sector to ensure all applicant and accredited organisations are aware of any necessary clarifications, interpretations, updates or changes to UKAS policy, requirements where issues have been raised, discussed and agreed at the above meetings. The content of these bulletins will be incorporated into relevant UKAS Publications (i.e. LAB 30 and RG 8) at their next revision.

Since Issue 6 the following sections have been introduced:

- [1] HSG248 Interpretation/Clarification for Testing Laboratories

- [4] RG 8 Section 10.4 Clarification on Quality Assurance requirements

The updated sections reflect:

The following items are included in this bulletin:

[1] HSG248 Interpretation/Clarification for Testing Laboratories

[2] Publication of LAB 30 Edition 5

[3] Surveying for Asbestos in Marine Vessels

[4] RG 8, Quality Assurance Clarification

- HSG248 Interpretation for Testing Laboratories

In May 2021 the Health and Safety Executive issued the Second Edition of Asbestos: The Analysts’ Guide. Simultaneously UKAS hosted a live webinar with the HSE, regarding the publication and the intentions for recognition for accreditation purposes.

Whilst the transition to the Second Edition has just been completed, the process during this period has identified a number of changes which require a degree of interpretation and/or clarification. For transition purposes laboratories have done this individually. However, going forwards, and for consistency in approach across the sector, recent discussion with HSE and Asbestos TAC stakeholders has taken place to agree on , based on its original intentions.

The following aspects provide interpretation on some of the perceived key changes and convey the outcomes from discussions to-date:

i. Analyst audits and reinspections – 4SC

The increase in internal auditing is welcomed by many analyst organisations as they can see the benefit to their organisation and their staff. However, it is recognised that we are in the midst of a pandemic and increasing this to 4 per year, at this time, could place a considerable outlay of resource and at a time when the industry is struggling to recruit.

It is therefore proposed, as a temporary measure, that the quantity of site audits be a minimum of 2 per analyst per year (with reasonable intervals in between). This revised minimum requirement will be included in LAB 30. There will be no amendment to the existing HSG248.

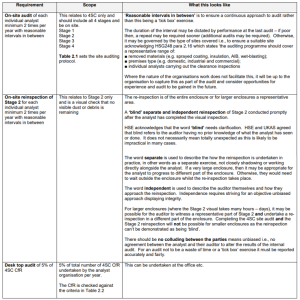

The table in Annex 1 sets out the temporary arrangements during the effects of COVID-19 pandemic including points of clarification for internal auditing of 4SC and further clarification on the intention and application of reinspection checks.

This temporary arrangement will be kept under review as will the evidence base to determine whether there has been any change in analyst performance from that seen in 2015.

ii. Use of solvents

The revised HSG248 now strengthens the requirement for sample preparation techniques whenever regulated asbestos types are not found in a material/product type that is known to have the potential to contain asbestos (see Paragraph A2.18). In the case of certain organic materials, e.g. floor tiles, plastics, bitumen, resin, rubber, mastics and adhesives, these materials/products should be subjected to treatment with a suitable organic solvent or combustion (at or below 400°C) (see Table A2.2). Solvent treatment may be undertaken on the “micro” scale by applying a few drops of appropriate solvent onto small sub-samples of material on a microscope slide/suitable glassware. This allows suspect fibres to be isolated, removed and cleaned, prior to mounting in appropriate refractive index liquid.

iii. No Asbestos Detected/2 points

The Second Edition has added the need to allocate 2 points to each sample analysed which is confirmed as not containing asbestos i.e. NAD (or No Asbestos Detected). For transition purposes the expectation has been for laboratories to adopt this change in-line with the Guidance. However, it is recognised that for certain products/materials, the time taken to analyse them will vary. Therefore, the premise for allocating 2 points, when the analysis identifies no asbestos is present, appears overly compensated for a narrow band of sample/material types. That said, recent technical discussions by the TAC have shown this issue to be complex and discussions to clarify the position are ongoing as a result.

To support the interpretation there is now opportunity for any appropriate body to submit an alternative proposal for consideration. The proposal must contain adequate and suitable evidence to justify the changes being requested. Further details on the requirements/timeline for any such proposal are detailed in Annex 2 below.

Once consensus has been reached on the interpretation of this revision, then further clarification will be provided. In the interim, laboratories are expected to implement the guidance as detailed in Table A2.10 of HSG248.

iv. Recording of timings for stereo and PLM

Paragraph A2.28 states: “The start and finish time of both the stereo-binocular evaluation and identification of fibres by PLM should be recorded.”

The process of using the stereo and polarised light microscopes in sample analysis is such that an analyst can use both scopes on one sample more than once in such analysis and as such, it is impractical to track accurate time observations. It is therefore agreed that the start/finish time will relate to the overall sample analysis process incurred on each sample.

v. Layered Samples

Paragraph A2.27 confirms that each layer in a sample should be examined as a separate entity. Paragraph A2.70 confirms that analysis of each layer will need to be recorded separately.

In terms of how points should be allocated when analysing a layered sample, it has been agreed that points shall be applied for the sample, no matter how many layers are encountered. The sample/material type will determine which category is to be applied, (Table A2.10) when determining if a 1- or 2-point allocation is needed for the sample in question.

vi. 5% reanalysis – frequency

Paragraph A2.74 states that for routine analyses a minimum overall QC check of 5% of re-analyses on new samples should be maintained.

Whilst accepted that this is in addition to the 20% of samples analysed in excess of the requirements as described in Table A2.10, the timeframe for completing the 5% checks is open to interpretation, although inferred it is daily, (as with the 20% over budget reanalysis).

It has been agreed that for labs where analysts are undertaking low sample analysis rates (e.g. x10 per day per analyst or less), then the 5% re-checks can be based on a longer timeframe, e.g. weekly or even monthly. However, where such timeframes are implemented into procedures, labs shall ensure that reanalysis is completed before the customer of the intended result(s) receives their final reported result, (e.g. via certificate/report).

vii. Bulk analyst – Personal sampling frequency

LAB 30, Section 6.2.4.2, currently requires laboratories to undertake air monitoring during bulk/soils analysis activities, on a periodic basis, determined by risk. Most laboratories undertake static tests to comply with this need on a monthly basis.

Paragraph A2.8 of HSG248 now conveys that such air monitoring should instead be done only as personal sampling on analysts, working within the sample preparation/identification area. It has been agreed that such personal air monitoring can also be extended beyond the monthly timeframe if suitable evidence exists, (via a risk-based approach) to justify the periodicity implemented. However all analysts must be covered in the monitoring programme at least annually and sooner if recently trained/authorised to undertake bulk identification.

- Publication of LAB 30 Edition 5

Superseding Edition 4, this will primarily be revised to implement the changes documented in HSG248, Second Edition.

The process for updating Lab 30 has already started. LAB 30 will include all relevant aspects of the changes brought about by the revised HSG248, including those as detailed above to support accreditation to ISO/IEC 17025. Public consultation on these changes will begin in the next few weeks. This will be an opportunity for all relevant accredited/applicant bodies to provide input to the requirements as documented.

- Surveying for Asbestos in Marine Vessels

The UKAS process for assessing and accrediting asbestos inspection bodies was developed at the request of the Health and Safety Executive (HSE) in 2001. The subsequent pilot scheme was based on a programme to support the requirements of MDHS100 in non-domestic premises.

Current schedules of accreditation for asbestos inspection are based on the initial scheme along with subsequent guidance as issued by the HSE. These are supported by ongoing assessment by UKAS of organisations accredited to ISO/IEC 17020 of domestic, commercial and industrial categories of land-based buildings.

For marine vessels used within international waters and registered with the International Maritime Organisation (IMO) the requirements for surveying of such ‘premises’ differ from the current UK guidance as currently published in HSG 264, and which UKAS accreditation of asbestos surveying is currently based. Although UKAS recognises that UK Regulations

cover the normal operation of marine vessels in UK waters and docks, separate accreditation will be required for those organisations that wish to undertake surveys of marine vessels to an accredited standard including:

- Cargo vessels

- Passenger vessels, and

- Off-Shore vessels and Facilities

as specified by the Safety Of Life At Sea (SOLAS) Convention Chapter II-1, Regulation 3.5.2 (1974 as amended) for the sole purpose of generating asbestos condition reports, (Initial, Verification and In-service, including management recommendations where appropriate).

This decision has been based on a pilot assessment which was tailored to address the specifics associated with surveying of marine vessels. This identified (amongst other aspects) that the technical competence required to undertake such surveys differed significantly from experiences associated with normal land-based building surveying.

UKAS would be willing to develop an accreditation programme for this sector to meet the needs of its customers and stakeholders (such as the Maritime and Coastguard Agency). However, it does recognise that work will be required in order to ensure the programme is fully effective in determining the competence of asbestos surveying on marine vessels, and in meeting relevant international guidelines and requirements as well the minimum requirements of ISO/IEC 17020. Therefore, dependent on feedback from stakeholders, if sufficient support for such a programme is received then UKAS will look at the viability for setting up a development project and steering committee to take this forward.

Any organisation with a keen interest in participating in such a pilot programme should contact Louise Wainwright at: [email protected]

UKAS considers marine vessels at this moment in time to mean boats/ships and (actively) mobile platforms. UKAS understands that a number of Inspection Bodies are involved with surveys within the marine sector. Therefore, where IBs have been surveying fixed rigs & platforms, they will be permitted to continue to do so under ‘industrial premises’, so long as competence has been suitably demonstrated. However, IBs should be aware that the UKAS position may change in the future pending input from marine stakeholders if a development project and steering committee is developed.

- RG 8 Edition 5 September 2021 – clarification on Section 10.4

This revision set out to qualify UKAS policy on the application of HSE guidance on the undertaking of resurveys as part of the necessary quality assurance measures for inspection bodies.

As part of the Guidance 10.4 in RG8 indicates that 4% as a minimum should be achieved by inspection bodies. However, this is to support the current HSG 264 guidance of around 5%, not replace it. Inspection bodies should still use the 5% as the standard they aim for as part of their implemented QA programme. Improvement will still be sought by UKAS if 5% is not demonstrated. Where 4% is not demonstrated then UKAS shall consider action(s) to address accordingly. When failings in this aspect are not seen to be suitably addressed, sanctions will be considered.

Annex 1

Annex 2

HSG 248 Asbestos: The Analysts’ Guide (Second Edition)

Requirements for any proposal to support the Receipt, Tracking, Recording and Quality Assurance of Bulk Material samples for identification purposes

With the introduction of the revised Guidance, recent feedback (21/12/21) from the trade bodies of NORAC and ATaC, on behalf of their members, has argued that the assignation of 2 points for all negative samples1 is not always appropriate.

In particular, it is suggested that some materials, where there is no reason to think that asbestos may be present, such as timber, plastic, plasterboard, NT cement products, Glasroc etc, would not require the additional time in preparation in support of the overall analysis. As such, where asbestos is not detected (NAD) the need to score 2 points in these cases is stated as not justified. The resulting proposal is that for materials such as these the score applied should therefore be afforded 1pt accordingly.

The intention of the scoring system is to manage more effectively the throughput of sample analysis by laboratories. The mechanism by which sample type/complexity could be reflected appropriately was detailed in HSG 248 (2005), with subsequent criteria (on sample numbers/points per analyst) added via the Asbestos TAC in 2014. However, it has been recently stated that the spectrum of samples being received by some laboratories now includes a higher proportion of NAD samples that would not have previously been taken, (TAC Meeting Jan 2022). Regardless of the reasons for this, (which are out with this particular document) it is recognised that Laboratories will continue to analyse such samples.

Whilst the reason why 2 points are allocated to sample types1 is recognised, there is a view by some that revised Guidance has not sufficiently prescribed the level of detail considered necessary to support Laboratories when managing NAD samples. In particular, recognising the appropriate rigour as applied for those NAD samples which may/may not be considered candidates for containing asbestos, but still ultimately provide an equally robust valid result, regardless of the approach (i.e. prep type) taken to achieve this. As such it has been suggested that the final points allocated should also be more reflective of this process. For the National Accreditation Body and H&S Regulator to react accordingly to these industry developments, appropriate evidence will be needed to support any potential tiered/layered approach to sample recognition.

An alternative proposal from an appropriate body may be submitted for consideration. To ensure such responses are timely a deadline of 1st March is provided. The proposal must contain adequate and suitable evidence to justify the changes being requested. The following aspects must be included in any proposal:

- HSG248 as issued will not change, but it may be possible for labs/associations having difficulties with the NAD points issue to jointly develop an alternative proposal on NADs and points, providing this alternative is at least equivalent to the standard set by HSG248.

- The transition timescale will not change, so for the present, 2 points per NAD must be implemented, regardless of sample type.

- There is no certainty that the alternative proposal would be accepted.

- The issue of an analytical certificate declaring NAD must reliably mean exactly that

- NAD 2 points addresses the need to assure quality of bulk ID analysis and prevent fatigue/potential inattention with concentrated microscope work and MSD/ergonomic issues so:

- Labs should have considered human factors aspects in their existing risk assessments

- Any alternative proposal should also address human factors

- The management measures which should be described, should consider additional quality assurance for any sample deemed appropriate for this adjusted testing pathway to ensure controls remain robust

- Layered samples should be considered

- Additional wet treatments should be considered and addressed where applicable (and pinch samples)

- Any list of materials or criteria set for samples that are to follow this adjusted testing pathway or treated outside HSG248 must be limited and specific with little scope for creative interpretation

- Consider surface contamination issues

- Very serious consideration should be given to how you will demonstrate that your proposal is equally effective or better than the robust testing proposed in HSG248 e.g. in identifying the absence of trace and fine asbestos.

Overall, the proposal must demonstrate that it is equivalent, if not better, than the existing Guidance, to retain analyst and public safety and the validity of testing results under accreditation requirements2.

Submissions to be forwarded in the first instance to George Sanders ([email protected]). UKAS will then forward these submissions to HSE for consideration as regulator.

1 – Table 2.10 (pg 141); Note 4 to Table A2.10; A2.18, (pg 116/117) which then refers to Table A2.2

2 – Whilst in support of the Regulation, requirements for Accreditation include the effective demonstration of compliance and competence to ISO/IEC 17025:2017. Therefore, any proposal needs to consider those aspects of the Standard that are relevant in support of any adjusted testing pathway, e.g. contract review, validation, ensuring the validity of test results, etc.

Glossary

ATaC – Asbestos Testing and Consultancy Association

HSG – Health & Safety Guidance

HSE – Health and Safety Executive

ID – Identification

MSD – musculoskeletal disorders

NAD – No Asbestos Detected

NORAC – National Organisation of Asbestos Consultants

TAC – Technical Advisory Committee

UKAS – United Kingdom Accreditation Service

To download a PDF version click here